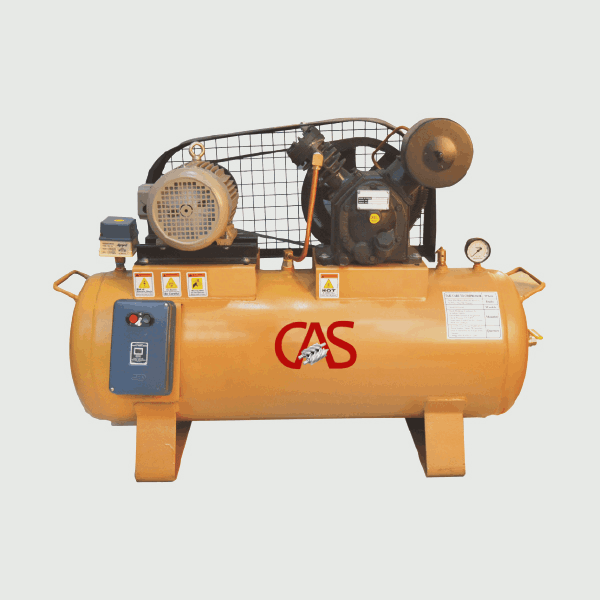

Two stage Oil lubricated Reciprocating Air Compressor

Two stage Oil lubricated Reciprocating Air Compressor

Our two stage air compressor are designed for optimum efficiency while requiring minimum maintenance to meet your demand of compressed air. And with an extensive service network and easy availability of spares, this compressor is undoubtedly the wisest choice for unparalleled performance in the long run.For small scale industries and entrepreneurs, our two stage high volume compressors provide the perfect match between low investment and maximum returns.

CORE VALUE THAT BENEFITS THE CUSTOMER

- High reliability : Robust internal parts and lesser service points ensures lower down time of the compressor

- Cost effective : Offers low life cycle cost with zero compromise on performance and quality

- Energy efficient : Best in class flow for specified HP with high efficiency IE2 & IE3 Motors

- Operator safety : Compressor design confirms to ASME design code and OSHA Safety standards.

Two stage Oil lubricated Reciprocating Air Compressor

| Model | Motor | No. of Cylinders | Piston Displacement Scfm |

Maximum Pressure | Air Receiver Ltrs. |

||

|---|---|---|---|---|---|---|---|

| HP | Scfm | Psig | Bar | ||||

| 734 | 2 | 7.46 | 2 | 7.46 | 175 | 12.3 | 160 |

| 734 | 3 | 11.25 | 2 | 11.25 | 175 | 12.3 | 160 |

| 742 | 5 | 17.35 | 2 | 17.35 | 175 | 12.3 | 225 / 250 |

| 753 | 7.5 | 26.40 | 2 | 26.40 | 175 | 12.3 | 250 / 300 |

| 7545 | 7.5 / 10 | 30 / 33 | 2 | 30 / 33 | 175 | 12.3 | 250 / 300 |

| 2600 | 7.5 / 10 | 33.5 / 37.2 | 2 | 33.5 / 37.2 | 175 | 12.3 | 250 / 300 |

| 771T2 | 10 / 12.5 | 40 / 49 | 2 | 40 / 49 | 175 | 12.3 | 300 / 500 |

| 715T | 15 / 20 | 63 / 81 | 3 | 63 / 81 | 175 | 12.3 | 500 |

| 725 T | 20 / 25 | 85 / 99 | 3 | 85 / 99 | 175 | 12.3 | 500 |

- Above models available on request for higher working pressure up to 17.5 Bar

- Standard package includes auto pressure switch, motor, starter, v-belt, oil sight glass, manual drain and ASME standard tank.

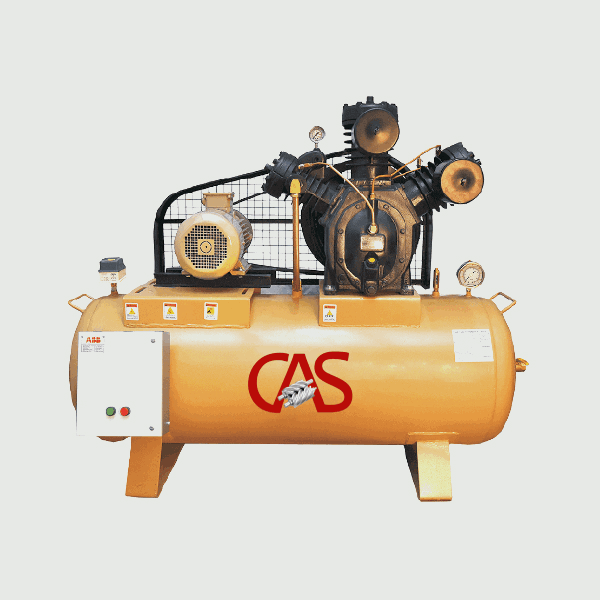

Multi Stage Oil lubricated High Pressure Reciprocating Compressor

Multi Stage Oil lubricated High Pressure Reciprocating Compressor

Our multi-stage high-pressure air compressors are designed for high-pressure applications. These compressors have extra heavy-duty components and are designed for minimum maintenance and maximum performance. High-pressure air compressors are widely used in power generation plant, PET blow molding industry, military, diving, laser cutting, circuit breaking and component testing. The compressors are designed for operator and plant safety with OSHA standards with belt guard, sealed safety valves as the compressors operate at higher pressures.

Multi Stage Oil lubricated High Pressure Reciprocating Compressor

| Model | Motor HP |

No. of Cylinders | SCFM | Maximum Pressure | Air Receiver Ltrs. |

||

|---|---|---|---|---|---|---|---|

| PD | FAD | Psig | Bar | ||||

| 731 | 3 | 2 | 7.40 | 5.20 | 500 | 35.15 | 150 |

| 731 | 5 | 2 | 10.80 | 7.80 | 500 | 35.15 | 200 |

| 77T2 | 10 | 2 | 32.23 | 21.70 | 500 | 35.15 | 300 |

| 77T2 | 12.5 | 2 | 36 | 23.60 | 500 | 35.15 | 300 |

| 715T2 | 15 | 3 | 41.25 | 32.41 | 500 | 35.15 | 500 |

| 715T2 | 20 | 3 | 49.50 | 37.70 | 640 | 45 | 500 |

| 715 TH | 15 | 3 | 48.60 | 41.10 | 500 | 35.15 | 500 |

| 715 TH | 20 | 3 | 65.42 | 54.30 | 370 | 25.80 | 500 |

| 715 TH | 25 | 3 | 88.30 | 74.00 | 370 | 25.80 | 500 |

| 715DP | 20 + 20 | 3 + 3 | 126.40 | 108.00 | 370 | 25.80 | 500 |

| 715DP | 25 + 25 | 3 + 3 | 176 | 148.00 | 370 | 25.80 | 500 |

- Standard package includes auto pressure switch, motor, starter, v-belt, oil sight glass, manual drain and ASME standard tank.